V-belts are manufactured for a working temperature of –30 °C to + 80 ° C according to ISO 4184, DIN2215 / 7753 and BS3790 standard and also meet requirements for oil and heat resistance.

Range:

- classic V-belts Z, A, B, C, D

• wedge belts SPZ, SPA, SPB and SPC

• v-belts raw edge gogged AX, BX, CX, XPZ, XPA, XPB and XPC

• power bands, Poly-V belts and V-belts according to customer specifications

• antistatic according to ISO

High performance timing belt

The optibelt OMEGA High Power high-performance timing belt was especially developed to meet the most demanding requirements.

The optimised tooth shape with indented tip significantly reduces noise levels.

Sections and lengths

Sections and lengths

| 3M | 111 – 1863 mm |

| 5M | 120 – 2525 mm |

| 8M | 288 – 4400 mm |

| 14M | 966 – 4578 mm |

| D5M | 565 – 1200 mm |

| D8M | 600 – 3600 mm |

| D14M | 1190 – 4578 mm |

| MXL | 2,64 – 40,4 in |

| XL | 6 – 63 in |

| L | 10,88 – 81,7 in |

| H | 23 – 170 in |

| XH | 50,75 – 175 in |

| XXH | 70 – 180 in |

| DXL | 15 – 31 in |

| DL | 18,75 – 60 in |

| DH | 24 – 170 in |

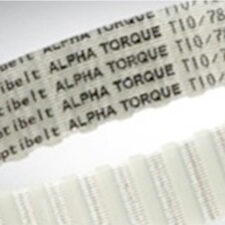

Timing belt – endless, cast polyurethane

The optibelt ALPHA TORQUE is made from abrasion-resistant polyurethane with a hardness of 86 Shore A. Its basic characteristics include unusually good oil resistance for polyurethane, as well as a certain resistance to acids and alkaline solutions.

Sections and lengths

| T2,5 | 107,5 – 950 mm |

| T5 | 150 – 1440 mm |

| T10 | 260 – 2250 mm |

| AT3 | 150- 714 mm |

| AT5 | 200 – 1500 mm |

| AT10 | 500 – 1940 mm |

| DT5 | 150 – 1100 mm |

| DT10 | 260 – 1880 mm |

| MXL | 60.96 – 812.80 mm |

| XL | 152.40 – 1701.80 mm |

| L | 314.33 – 1524.00 mm |

Match your pulleys to your belts for extended service life

The superior quality of our pulleys can significantly extend belt life, which helps to reduce the total cost of ownership of your machinery. We offer a wide variety of pulleys, in all types of profile. These include wedge belt, V-belt and narrow wedge belt pulleys, plus classical and metric timing pulleys and more.

Reduce maintenance costs with robust quality chains

Mean-time-between-failures (MTBF) is an important measure of reliability, and is critical in power transmission systems. Robust chain drives extend mean-time-between-failures, which reduces maintenance costs.

Features

- All products conform to ISO, and standards including ANSI, DIN and JIS

- Available in many standard product types

- Chains work from –20 to +150°C (stainless steel chains work up to 400°C)

Benefits

- Raw materials tested against tight specifications

- Processes such as annealing and shot peening further enhance performance

Calculation tools available

Selecting a power transmission component can be challenging, especially when it is a fundamental part like a sprocket.

Products must be available in many sizes, to fit a variety of design envelopes – and avoid the need for customised parts. With our comprehensive range, you will easily find the correct sprocket size for your application.

Features and benefits

- Manufactured according to ISO606 & ASME B29.100 standard

- Available in plate, single hub and double hub configurations

- Made from high-grade steel and carbon steel

- Optional taper bushes simplify installation and removal

- Special products made from grey cast iron HT250 or cast iron 250

- Surface treatment, including black oxide, available on request

Simplify installations with easy-to-fit, high-quality bushings and hubs

Bushings and hubs are available in many variants, offering specific benefits in power transmission applications ranging from automotive to paper making.

Features:

- Wide range of metric and imperial bore sizes available

- Fabricated from high-quality steel

- Easily installed and removed using basic tools

Benefits:

- Weld-on hubs made from premium carbon steel

- Phosphate coating and blackening raise corrosion resistance

SH bushings withstand high torques and axial loads, and extreme heat and cold

Machine designers are under pressure to raise the performance of power transmission systems, in the face of diminishing time and resources.

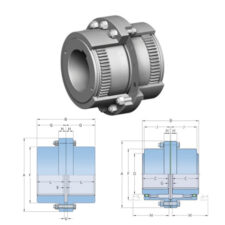

A diversity of coupling systems, including customised products, helps these systems work effectively and efficiently. Factors such as size and torque requirements determine the most appropriate coupling to use.

We offer all the main types, including grid, gear, flex and jaw couplings. In addition we supply OK couplings, which use oil injection for mounting and dismounting, and flexible shaft couplings.