V-belts are manufactured for a working temperature of –30 °C to + 80 ° C according to ISO 4184, DIN2215 / 7753 and BS3790 standard and also meet requirements for oil and heat resistance.

Range:

- classic V-belts Z, A, B, C, D

• wedge belts SPZ, SPA, SPB and SPC

• v-belts raw edge gogged AX, BX, CX, XPZ, XPA, XPB and XPC

• power bands, Poly-V belts and V-belts according to customer specifications

• antistatic according to ISO

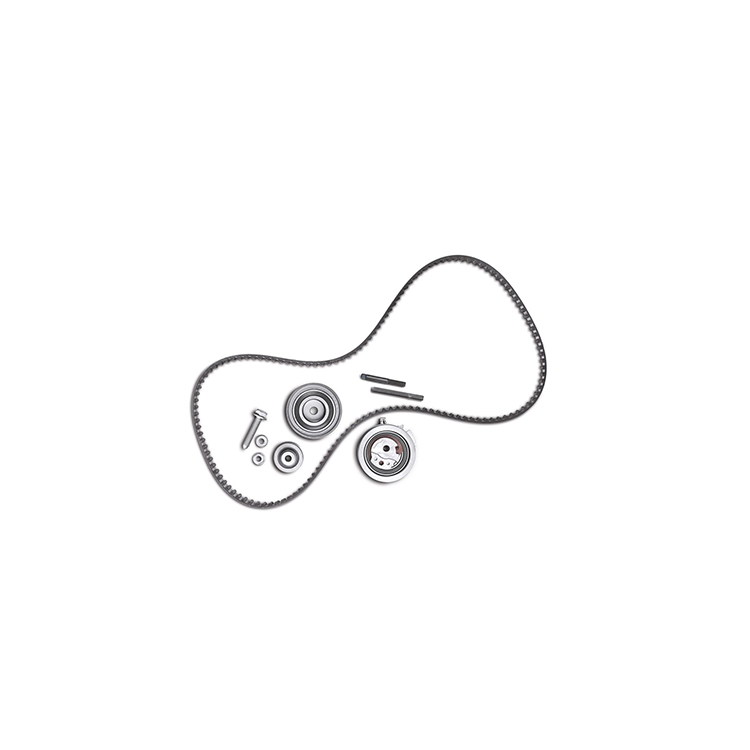

High performance timing belt

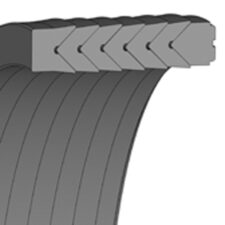

The optibelt OMEGA High Power high-performance timing belt was especially developed to meet the most demanding requirements.

The optimised tooth shape with indented tip significantly reduces noise levels.

Sections and lengths

Sections and lengths

| 3M | 111 – 1863 mm |

| 5M | 120 – 2525 mm |

| 8M | 288 – 4400 mm |

| 14M | 966 – 4578 mm |

| D5M | 565 – 1200 mm |

| D8M | 600 – 3600 mm |

| D14M | 1190 – 4578 mm |

| MXL | 2,64 – 40,4 in |

| XL | 6 – 63 in |

| L | 10,88 – 81,7 in |

| H | 23 – 170 in |

| XH | 50,75 – 175 in |

| XXH | 70 – 180 in |

| DXL | 15 – 31 in |

| DL | 18,75 – 60 in |

| DH | 24 – 170 in |

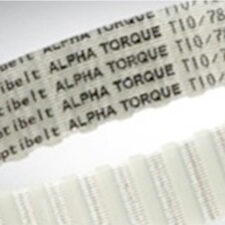

Timing belt – endless, cast polyurethane

The optibelt ALPHA TORQUE is made from abrasion-resistant polyurethane with a hardness of 86 Shore A. Its basic characteristics include unusually good oil resistance for polyurethane, as well as a certain resistance to acids and alkaline solutions.

Sections and lengths

| T2,5 | 107,5 – 950 mm |

| T5 | 150 – 1440 mm |

| T10 | 260 – 2250 mm |

| AT3 | 150- 714 mm |

| AT5 | 200 – 1500 mm |

| AT10 | 500 – 1940 mm |

| DT5 | 150 – 1100 mm |

| DT10 | 260 – 1880 mm |

| MXL | 60.96 – 812.80 mm |

| XL | 152.40 – 1701.80 mm |

| L | 314.33 – 1524.00 mm |

Match your pulleys to your belts for extended service life

The superior quality of our pulleys can significantly extend belt life, which helps to reduce the total cost of ownership of your machinery. We offer a wide variety of pulleys, in all types of profile. These include wedge belt, V-belt and narrow wedge belt pulleys, plus classical and metric timing pulleys and more.

Reduce maintenance costs with robust quality chains

Mean-time-between-failures (MTBF) is an important measure of reliability, and is critical in power transmission systems. Robust chain drives extend mean-time-between-failures, which reduces maintenance costs.

Features

- All products conform to ISO, and standards including ANSI, DIN and JIS

- Available in many standard product types

- Chains work from –20 to +150°C (stainless steel chains work up to 400°C)

Benefits

- Raw materials tested against tight specifications

- Processes such as annealing and shot peening further enhance performance

Calculation tools available